Machine Room (MR)

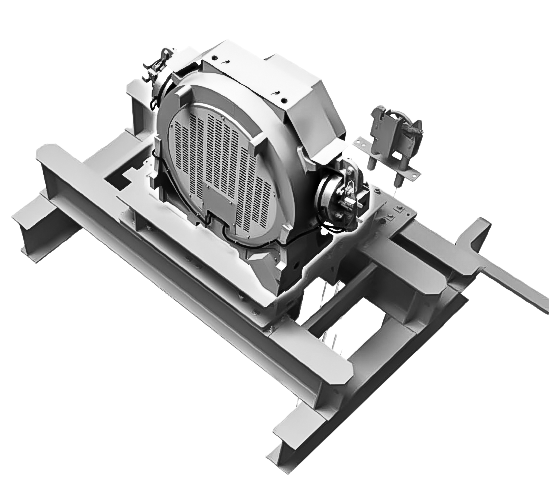

The Elevator Machine Room (MR) is a crucial part of any high-performance elevator system, housing essential components such as the traction machine, control panel, brake system, and power supply. These components work together to ensure smooth, efficient, and safe elevator operations.

A well-maintained Elevator Machine Room enhances system reliability, reduces operational costs, and ensures passenger safety. At Isuzu Elevator, we specialize in designing efficient and space-optimized machine rooms that meet modern building standards and energy efficiency regulations.

Function of the Elevator Machine Room: Ensuring Smooth and Safe Operation

- The Function of the Elevator Machine Room is to control, regulate, and power the movement of the elevator system. Without a properly designed machine room, the elevator would face performance issues, frequent breakdowns, and safety risks.

Key Functions of the Elevator Machine Room:

- Controls Elevator Motion: The traction machine and motor drive regulate elevator movement, ensuring smooth acceleration and precise stopping.

- Enhances Passenger Safety: The braking system and emergency power backups prevent malfunctions and ensure safe vertical mobility.

- Optimizes Energy Consumption: Advanced machine room designs include energy-efficient motors and regenerative drive technology to reduce electricity usage.

- Prevents System Overheating: A properly ventilated Elevator Machine Room ensures that components like motors and controllers remain cool and operational.

A well-designed Elevator Machine Room plays a vital role in keeping modern elevators efficient, durable, and safe.

Key Components of an Elevator Machine Room: Essential Parts for Performance

- The Key Components of an Elevator Machine Room include various mechanical and electrical systems that work together to drive the elevator efficiently.

Traction Machine & Motor: The Driving Force

- The traction machine is responsible for lifting and lowering the elevator cabin. It operates using an electric motor that powers steel hoist ropes over the traction sheave, ensuring smooth movement and controlled stopping.

Control Panel & Drive System: The Intelligence Behind Elevator Movement

The elevator control panel functions as the brain of the Elevator Machine Room, managing speed, floor selection, and safety mechanisms. Key features include:

- Variable Frequency Drive (VFD) for energy-efficient speed control.

- Microprocessor controllers for intelligent elevator movement.

- Safety monitoring systems to detect malfunctions and activate emergency stops.

Brake System: Critical for Passenger Safety

The brake system ensures that the elevator stops securely at each floor and prevents sudden movement in case of power failures. Electromagnetic brakes are commonly used in modern Elevator Machine Rooms for enhanced safety and reliability.

Power Supply & Backup System: Ensuring Operation During Power Outages

To prevent disruptions during power failures, an Elevator Machine Room includes:

- Uninterruptible Power Supply (UPS) to keep the system operational.

- Regenerative drive technology that captures and reuses excess energy to improve efficiency.

Ventilation & Cooling System: Protecting Critical Elevator Components

A well-ventilated Elevator Machine Room prevents overheating of motors and electrical components, ensuring long-term system reliability. Cooling fans and air conditioning units help maintain an optimal operating temperature.

- At Isuzu Elevator, we integrate advanced technology to design high-performance Elevator Machine Rooms that offer efficiency, safety, and durability.

Features & Advanced Technology in Passenger Elevators

Maintenance & Inspection Services: Ensuring Long-Term Elevator Performance

Regular Elevator Machine Room Maintenance is essential for ensuring safety, preventing malfunctions, and extending the lifespan of elevator components. A well-maintained machine room helps to keep the traction machine, control panel, and power systems in optimal working condition, reducing the risk of unexpected failures. Routine inspections are critical in identifying early signs of mechanical wear, electrical faults, or overheating issues, allowing for proactive repairs before major breakdowns occur.

At Isuzu Elevator, we offer comprehensive maintenance programs tailored to the specific needs of each building and elevator type. Our expert technicians conduct monthly, quarterly, and annual inspections, ensuring compliance with Japan’s strict safety regulations. We utilize advanced diagnostic tools to monitor motor performance, braking efficiency, and power supply stability, minimizing elevator downtime. In addition to regular preventive maintenance, we provide rapid repair services, ensuring that any technical issues are resolved promptly and efficiently.

One of the key benefits of Isuzu Elevator’s maintenance services is the integration of smart monitoring technology. Our real-time monitoring systems allow building managers to track elevator performance remotely, receive automated alerts for potential issues, and optimize maintenance schedules. This data-driven approach enhances operational efficiency, prevents unexpected shutdowns, and significantly reduces maintenance costs. With Isuzu Elevator’s expert maintenance team, property owners can be assured of continuous, safe, and energy-efficient elevator operation.

Passenger Elevator FAQs

An Elevator Machine Room (MR) is a dedicated space that houses essential elevator components, including the traction machine, control panel, brake system, and power supply. It ensures the smooth operation, safety, and efficiency of an elevator system.

A typical elevator machine room includes a traction machine, motor drive, control panel, brake system, power backup, and ventilation system. Each component plays a crucial role in ensuring the elevator runs safely and efficiently.

A Machine Room (MR) elevator requires a separate space above or beside the shaft to house the traction motor and control system. In contrast, a Machine Room-Less (MRL) elevator integrates the motor and drive system within the shaft, eliminating the need for a separate machine room, making it a space-saving solution.

The traction motor, control panel, and electrical systems in a machine room generate significant heat. Without proper ventilation or cooling systems, these components can overheat, leading to performance issues, increased energy consumption, and potential safety risks.

Regular Elevator Machine Room Maintenance should be conducted monthly, quarterly, and annually to ensure optimal performance. Inspections should focus on mechanical wear, electrical connections, brake performance, and system efficiency to prevent unexpected breakdowns.

Elevator machine rooms must comply with Japanese safety standards (JIS), global ISO regulations, and local building codes. These standards include fire-resistant construction, restricted access control, proper labeling, and emergency power backup systems to ensure safe operations.

Yes, some older machine room-based elevators can be retrofitted into MRL systems, depending on shaft size, building structure, and technical feasibility. Isuzu Elevator provides customized modernization solutions to upgrade older elevators for better efficiency and space utilization.

Modern machine rooms integrate energy-saving technologies like Variable Frequency Drives (VFDs), regenerative braking systems, and high-efficiency motors. These innovations help reduce electricity consumption, lowering operational costs and contributing to a greener, more sustainable building.

Most elevator machine rooms are equipped with an Uninterruptible Power Supply (UPS) or backup generator, ensuring that elevators can operate safely during power outages. Additionally, emergency braking systems keep the elevator stationary until power is restored.

For customized elevator machine room solutions, Isuzu Elevator offers tailor-made designs, expert consultation, and advanced technology integration. Whether it’s for commercial, residential, or industrial buildings, our team of specialists can provide the ideal solution to enhance safety, efficiency, and performance.